The Technology of Precision Additive

Our groundbreaking solutions are purpose-built for quality assurance. We will set a new standard for LPBF through a combination of proprietary technologies and innovations.

Our groundbreaking solutions are purpose-built for quality assurance. We will set a new standard for LPBF through a combination of proprietary technologies and innovations.

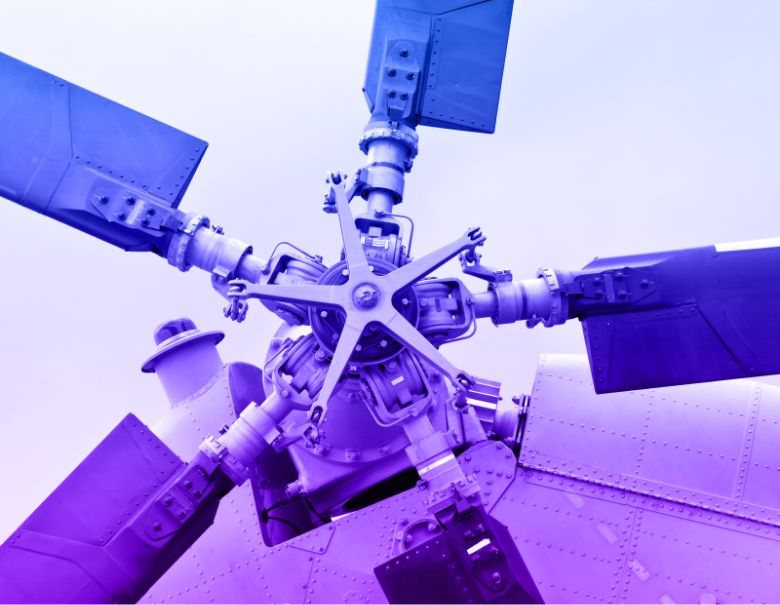

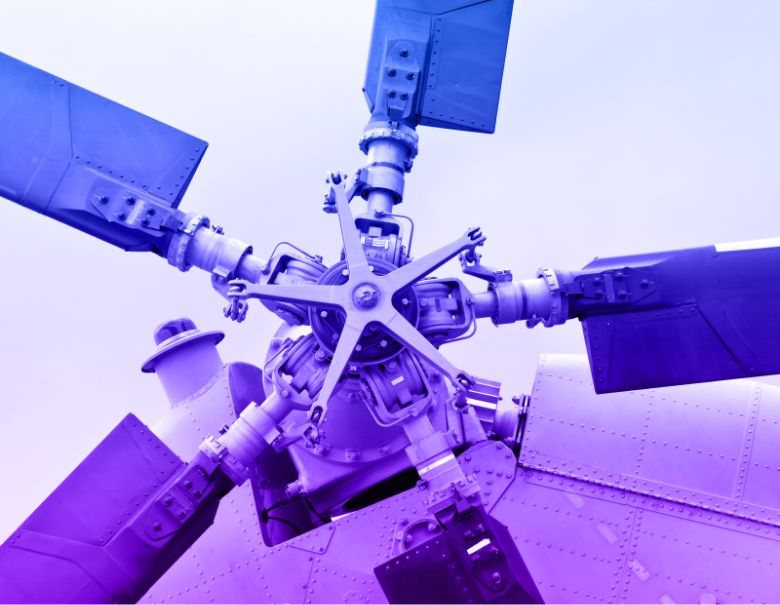

A cornerstone of this innovation is our SSLM™ laser beam system, which delivers superior melt-pool control, ensuring that each layer is deposited with extreme accuracy and quality.

A key innovation in our approach to LPBF is the ability to process reactive materials, including magnesium alloys, which have become increasingly difficult to source through traditional supply chains. Our 3D+ Printing technology enables the reliable production of these challenging materials, providing a vital alternative supply source for critical components.

Contact us to learn more about our innovative processes.

Precision Additive Qualification (PAQ) is a software solution that aggregates and analyzes data from Precision Additive Controls (PAC), Precision Intelligent Analysis (PIA), and Precision Intelligent Prediction (PIP). PAQ generates a comprehensive report that provides a structured assessment of LPBF processes, delivering valuable insights for qualification and optimization. Coupons never tell the full story, part size and shape matter, and PAQ accounts for this.

Our printers offer an optional hybrid capability, combining 3D printing with subtractive manufacturing (CNC machining) in a single system. This integration is especially beneficial for reactive material processing, enabling precise surface finishing while preserving material integrity. It also improves dimensional accuracy and enhances the surface finish of internal structures that are difficult to refine through traditional post-processing. Additionally, the hybrid option can reduce cycle times by minimizing delays associated with separate finishing steps.